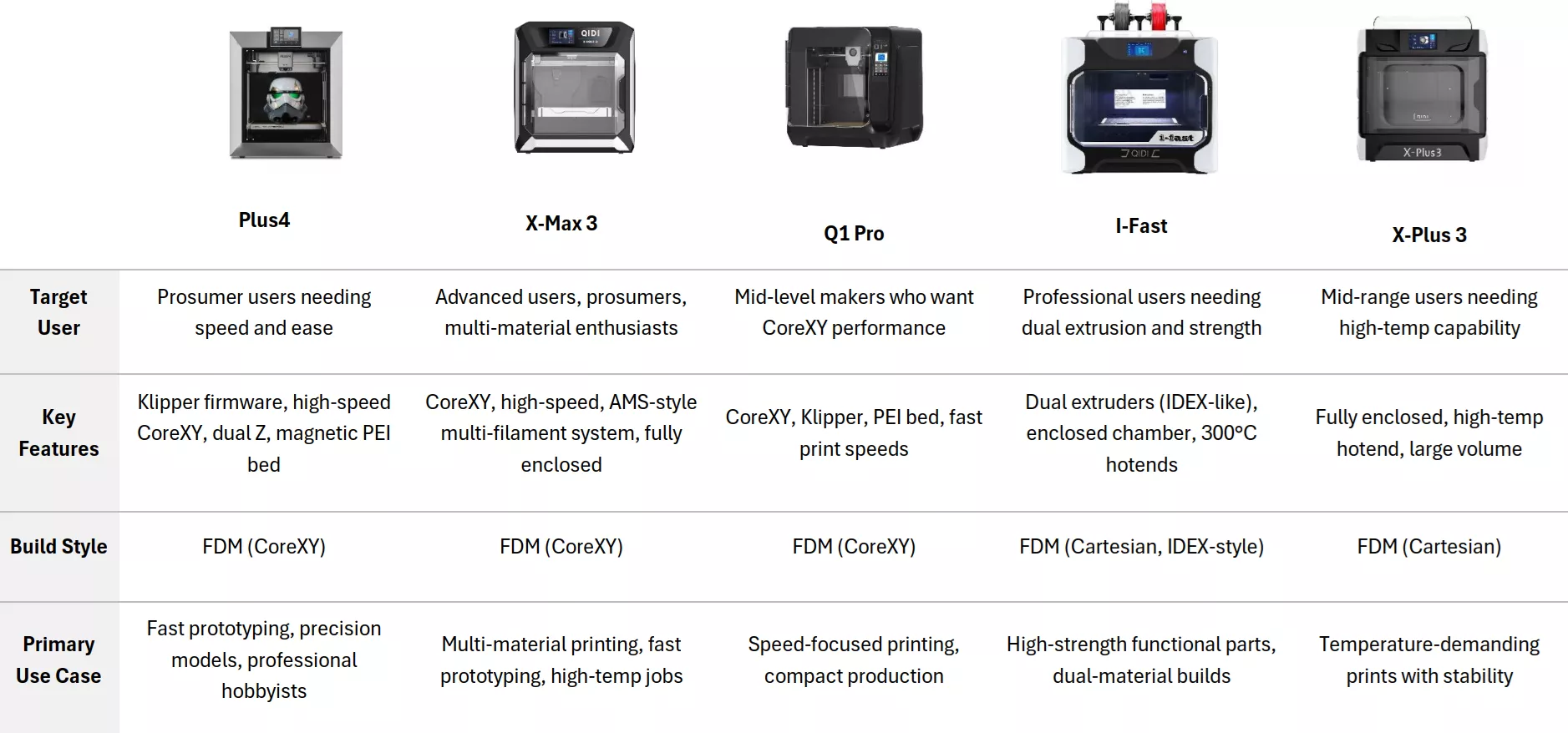

QIDI Tech, founded in 2014, has steadily built its reputation as a high-performance, mid-to-prosumer 3D printing brand. Known for fully enclosed machines, dual-extruder options, and a focus on engineering-grade materials, QIDI positions itself between consumer and industrial use. Models like the X-Max 3, X-Plus 3, and i-Fast are built for users who want long-term reliability, material versatility, and a semi-professional workflow.

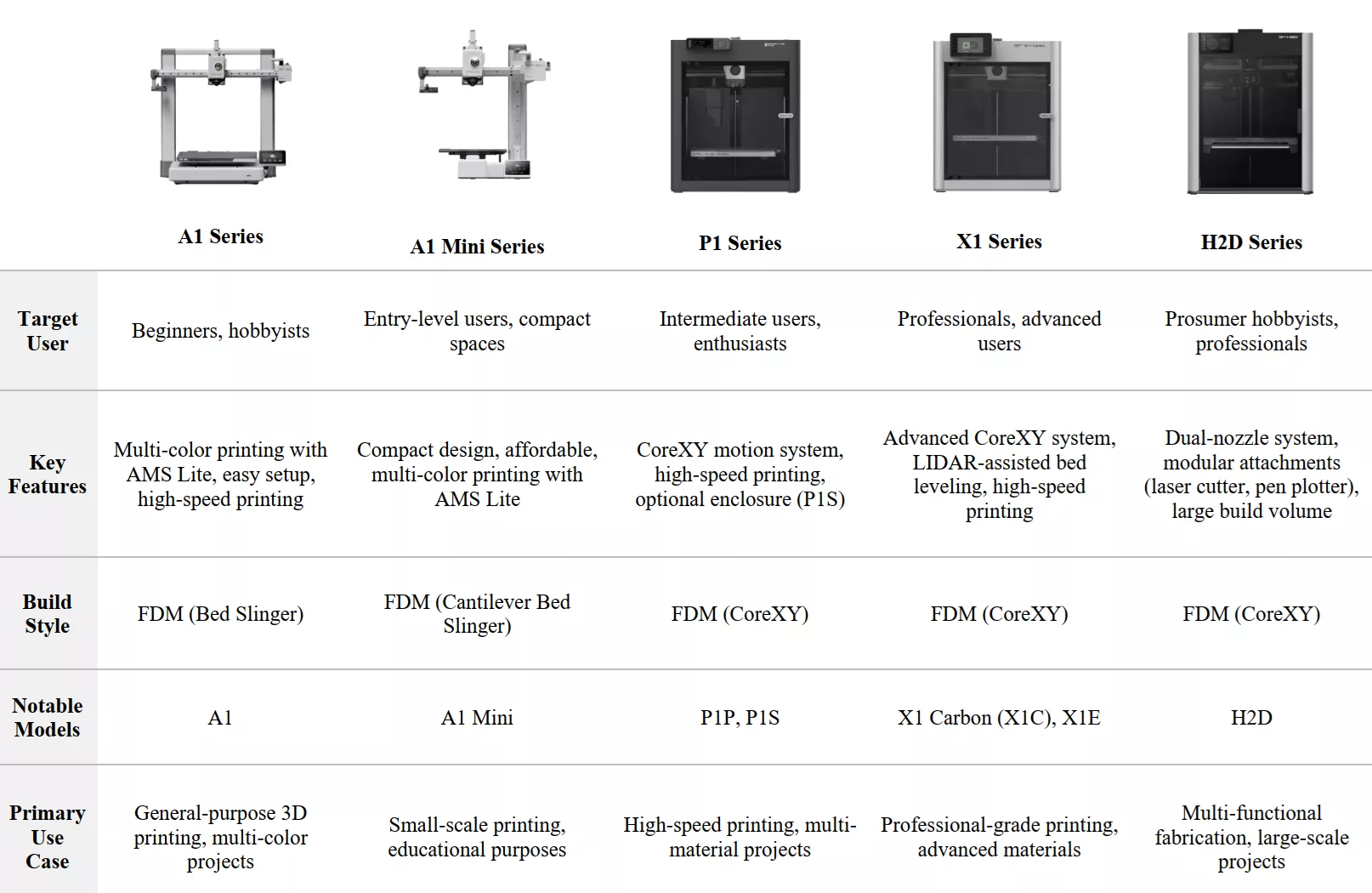

Bambu Lab, a newer player launched by former DJI engineers, has made waves with its automation-focused, high-speed machines. With innovations like LIDAR-based calibration, AMS (Automatic Material System), and robust CoreXY motion systems, Bambu delivers a slick, tightly integrated experience ideal for users who value speed and polish over open customization.

Product Selection

🟦 QIDI Tech combines industrial-grade features with consumer-friendly pricing, especially in enclosed CoreXY machines. From prosumer builds to multi-material setups, it’s tailored for users who want high performance with polish.

🟪 Bambu Lab brings a sleek, high-tech approach to 3D printing — fast, smart, and beginner-friendly. With innovations like LIDAR calibration and the AMS system, it’s perfect for prosumers and professionals who want speed without tinkering.

Ease of Use

🟦 QIDI is friendly but leans toward manual control. QIDI Print is straightforward, and machines ship mostly assembled, yet dual-extruder adjustment and chamber prep demand more user involvement.

🟪 Bambu Lab provides frictionless printing: auto-bed leveling, flow calibration, remote monitoring, and a visual slicer make setup nearly effortless. The AMS manages multiple spools with little input.

✅ Bambu Lab is easier for beginners and busy users; QIDI rewards hands-on tuning.

Cost & Affordability

🟦 QIDI offers the X-Plus 3 and Q1 Pro at about 700–900 USD, while the X-Max 3 and i-Fast sit around 1 400–1 800 USD — strong value for enclosed, high-temp machines.

🟪 Bambu Lab prices aggressively: A1 Mini Combo under 300 USD and X1C + AMS bundle near 1 200 USD. Accessories and branded materials can raise total cost.

✅ Bambu offers high-end speed for less; QIDI delivers industrial stability without a huge premium.

Print Quality & Speed

🟦 QIDI printers like the X-Max 3 and Q1 Pro produce clean, dimensionally accurate parts, especially with engineering materials. CoreXY architecture and advanced motion tuning allow speeds up to 600 mm/s while retaining detail. Older models such as the X-One 2 print more slowly but remain very stable.

🟪 Bambu Lab machines such as the X1-Carbon and P1P maintain excellent quality at default speeds of 250–300 mm/s. Active vibration compensation and smart calibration keep edges sharp even when printing fast, though the finest details still improve if speeds are reduced.

✅ Bambu Lab delivers higher overall speed with near-pristine quality; QIDI matches print precision but is less fluid and hands-free.

Material Compatibility

🟦 QIDI excels here. Most CoreXY models are fully enclosed, include dual extruders, 300–350 °C hotends, and hardened parts, letting users print PLA, PETG, TPU, ABS, PC, Nylon, and carbon-fiber composites without extra mods. Hotends swap quickly for material-specific jobs.

🟪 Bambu Lab supports ABS, PA, and fiber-filled filaments on higher-end models, but the AMS works best with Bambu-branded spools. Third-party materials, especially in multi-material prints, need extra slicer tuning.

✅ QIDI Tech wins for material flexibility and pro-grade, high-temp filament support.

Build Volume & Variety

🟦 QIDI spans compact units like the X-Smart 3 to large CoreXY models such as the X-Max 3 (325 × 325 × 315 mm) and i-Fast, offering IDEX and multi-material capabilities.

🟪 Bambu Lab focuses on desktop volumes: 180 × 180 × 180 mm (A1 Mini) up to 256 × 256 × 256 mm (X1/P1 series) with no large-format option yet.

✅ QIDI wins for variety and large-scale choices; Bambu Lab stays desktop-class.

Reliability & Durability

🟦 QIDI uses metal frames, dual rails, and enclosed chambers designed for long, worry-free jobs. Firmware is stable, and modular parts simplify upkeep.

🟪 Bambu Lab hardware is robust, yet users sometimes see firmware bugs, AMS jams, or connectivity quirks that need software updates.

✅ Tie - QIDI Tech slightly takes the lead on mechanical stability and fewer software interruptions.

Maintenance

🟦 QIDI offers tool-less nozzle swaps, clear diagnostics, and easy access to hotends and chambers, making routine care predictable even for advanced materials.

🟪 Bambu Lab is low-maintenance day-to-day, but AMS troubleshooting or deep internal work can be complex because of the tightly integrated design.

✅ QIDI is more serviceable and upgrade-friendly; Bambu Lab is simpler short-term but harder to repair in depth.

Technology & Features

🟦 QIDI focuses on practical engineering: dual Z-axes, independent dual extruders, fully enclosed heated chambers, and industrial hotends — less flashy but production-ready.

🟪 Bambu Lab leads with LIDAR calibration, AMS multi-material printing, AI camera, cloud sync, and silent CoreXY motion — features rarely seen at its price.

✅ Bambu Lab wins for cutting-edge convenience; QIDI targets professional robustness.

🟦 Choose QIDI Tech if you are:

- A professional or prosumer working with high-temp or composite materials

- Printing functional parts, engineering prototypes, or production runs

- Someone who values hardware flexibility and long-term durability

🟪 Choose Bambu Lab if you are:

- A creative or engineer seeking fast, hands-off performance

- Interested in high-tech automation, AMS, and smart workflow tools

- Willing to trade open customization for a sleek, app-integrated experience

Conclusion

QIDI Tech is the go-to for users who want rock-solid enclosures, pro-grade material support, and reliability under long workloads. Bambu Lab, meanwhile, offers a futuristic experience with unbeatable speed and automation. Each brand serves a different tier of the advanced user spectrum — one rooted in industrial utility, the other in high-tech efficiency.