Highlights

Strong print quality across both FDM and resin printer lineups

Extensive material compatibility (especially with resin and flexible filaments)

Diverse product range from budget-friendly to professional-grade machines

Excellent value for money with aggressive pricing

Fast assembly and beginner-friendly setup on most models

Rapid technology updates with new features like multi-material printing (Kobra 3 Combo)

Mixed reputation for customer support and occasional quality control issues

Active user community with solid third-party slicer and modding support

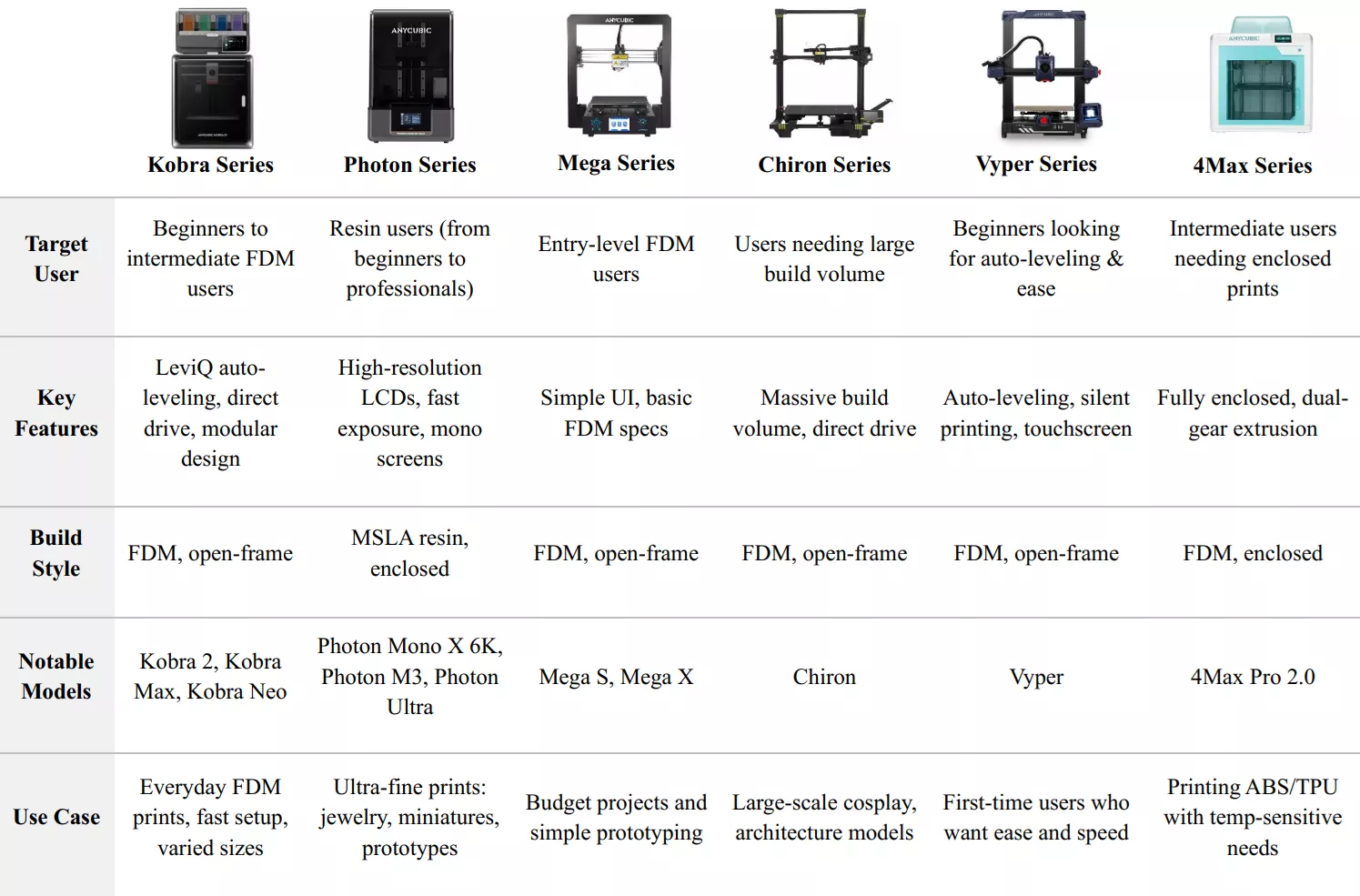

Founded in 2015, Anycubic quickly became one of the most recognizable names in consumer 3D printing by offering affordable, high-quality machines to a wide range of users. The brand has established a strong presence in both the FDM (Fused Deposition Modeling – printers that use heated plastic filament) and resin printing markets, with iconic models like the Photon series revolutionizing desktop resin printing and the Kobra series offering competitive features in the FDM space. Anycubic is known for delivering impressive value, user-friendly machines, and rapid innovation cycles, although occasional concerns around customer support and quality control persist. Overall, Anycubic remains a go-to choice for hobbyists, makers, and even small businesses looking for reliable printers without breaking the bank.

Product Selection

4.1 /5

Anycubic offers a well-balanced mix of affordability and out-of-the-box performance, especially in both resin (Photon) and FDM (Kobra) segments. It’s an ideal choice for beginners and intermediate users looking for value without hassle.

Ease of Use

3.7 /5

Ease of use is a major focus for Anycubic. Most machines ship semi-assembled (some parts pre-installed, others simple to attach), requiring minimal setup. Features like automatic bed leveling (a sensor helps align the print bed with the nozzle), touchscreen interfaces, and intuitive slicers (software that converts 3D models into printer instructions – e.g., Photon Workshop for resin printers) make the printers accessible even to first-time users. However, firmware (the internal software that runs the printer) and slicer tools can occasionally feel less polished compared to competitors like Prusa or Bambu. Nonetheless, the onboarding experience (the initial user journey from unboxing to first print) is smooth for the majority of users.

Cost & Affordability

4.8 /5

Affordability remains a cornerstone of Anycubic’s appeal. Most entry-level models (like Kobra Go or Photon Mono) are priced under $300, while mid-range offerings (like Kobra Plus or Photon Mono X) land between $400–$700. Even flagship products like the Kobra 3 Combo or Photon M3 Premium stay competitively priced below $1,000–$1,200. Given the feature sets offered, Anycubic provides some of the best cost-to-performance ratios in both the FDM and resin categories.

Print Quality & Speed

3.8 /5

Anycubic printers generally offer excellent print quality for their price class. FDM models like the Kobra series (Kobra 2, Kobra Go, Kobra Plus) produce detailed, consistent prints with minimal tuning needed. Meanwhile, resin models such as the Photon Mono 4K, Mono X, and M3 series deliver exceptional surface finish and fine detail, rivaling machines that cost much more. Printing speeds vary by model: traditional FDM printers like the Kobra Go are moderate (typically around 60–100mm/s), while newer machines like the Kobra 3 Combo offer faster, multi-material printing (the ability to print with more than one filament at a time). Photon resin printers also benefit from fast exposure times (the amount of time light cures a layer of resin), making them highly efficient for detailed prints.

Material Compatibility

4.1 /5

Material support is a strong point for Anycubic. FDM printers can handle PLA (easy-to-use biodegradable filament), PETG (stronger, more heat-resistant), TPU (rubbery flexible plastic), and occasionally ABS (a durable plastic that requires heat management)—especially on newer enclosed models (printers with a closed frame to control temperature) like the Kobra 3 Max Combo. Meanwhile, resin printers support standard, flexible, and tough resins (liquid materials that harden when exposed to UV light). Anycubic sells its own branded materials but remains open to third-party filaments and resins (users are not locked into using only the brand's consumables). Their hardware generally tolerates a wide range of settings, making experimentation accessible.

Build Volume & Variety

4.2 /5

Anycubic’s product lineup is diverse, offering a wide range of build volumes (the maximum printable area of a 3D printer). FDM printers like the Kobra Plus and Kobra 3 Max Combo offer large-format printing (300mm and up), ideal for cosplay props or big prototypes. Compact models like the Kobra Go suit users with limited space. On the resin side, the Photon Mono series ranges from small to medium build areas—perfect for miniatures, jewelry, or high-detail prototypes. This variety ensures that Anycubic has a product for nearly every user need and workspace size.

Reliability & Durability

3.6 /5

Mechanical reliability is generally good, especially considering the pricing. Many users report hundreds of hours of use on models like the Kobra Plus and Photon Mono without major issues. However, some customer feedback points to factory defects or component failures (e.g., faulty LCD screens in resin printers or power supplies) particularly in early batches of new models. While Anycubic’s customer support has improved over time, response times and warranty claims can still be inconsistent depending on region. With proper maintenance, however, long-term durability is generally solid.

Maintenance

4.2 /5

Maintenance needs are moderate. FDM printers require typical upkeep such as nozzle cleaning (removing built-up plastic from the print head), belt tension checks (ensuring movement belts are tight), and bed surface cleaning. Resin printers require more involved care: resin vat cleaning (removing leftover liquid resin), FEP sheet replacement (a transparent film that separates the resin and light source), and filter management. That said, Anycubic designs these processes to be straightforward. Spare parts are widely available through Anycubic’s store and third-party vendors, and a strong online community provides ample troubleshooting help.

Technology & Features

3.9 /5

Anycubic continues to innovate aggressively. Newer FDM models like the Kobra 3 Combo introduce multi-material printing and even CoreXY architecture (a motion system that allows faster, more stable printing by moving the printhead diagonally instead of one axis at a time). Resin printers feature monochrome LCDs (which cure resin faster and last longer), anti-aliasing (a feature to smooth out edges of prints), and improved cooling systems for better performance. Features like automatic leveling, flexible build plates (for easy part removal), Wi-Fi printing, and even AI-assisted monitoring (in upcoming models) show Anycubic’s commitment to keeping up with premium competitors.

Conclusion

Anycubic has firmly positioned itself as a leader in affordable 3D printing, offering strong value in both filament and resin printer markets. While not without flaws—particularly around quality control and customer support—their rapid innovation, expanding ecosystems, and easy-to-use products make them a favorite among hobbyists and semi-professionals alike. For anyone seeking an accessible, feature-rich printer without a steep learning curve or high cost, Anycubic remains an excellent and dependable choice.