Highlights

Solid print quality across a wide range of budget and mid-tier models

Extensive material compatibility with open filament system

Massive model variety from compact Ender 2 Pro to large-format CR-10 series

Highly modular and upgradable with active community ecosystem

Ease of use improving steadily with newer models (auto-leveling, touchscreens)

Excellent affordability across nearly all product categories

Rapid innovation cycle introducing high-speed and CoreXY models (K1, K1 Max)

Mixed quality control issues noted on earlier generations, improving over time

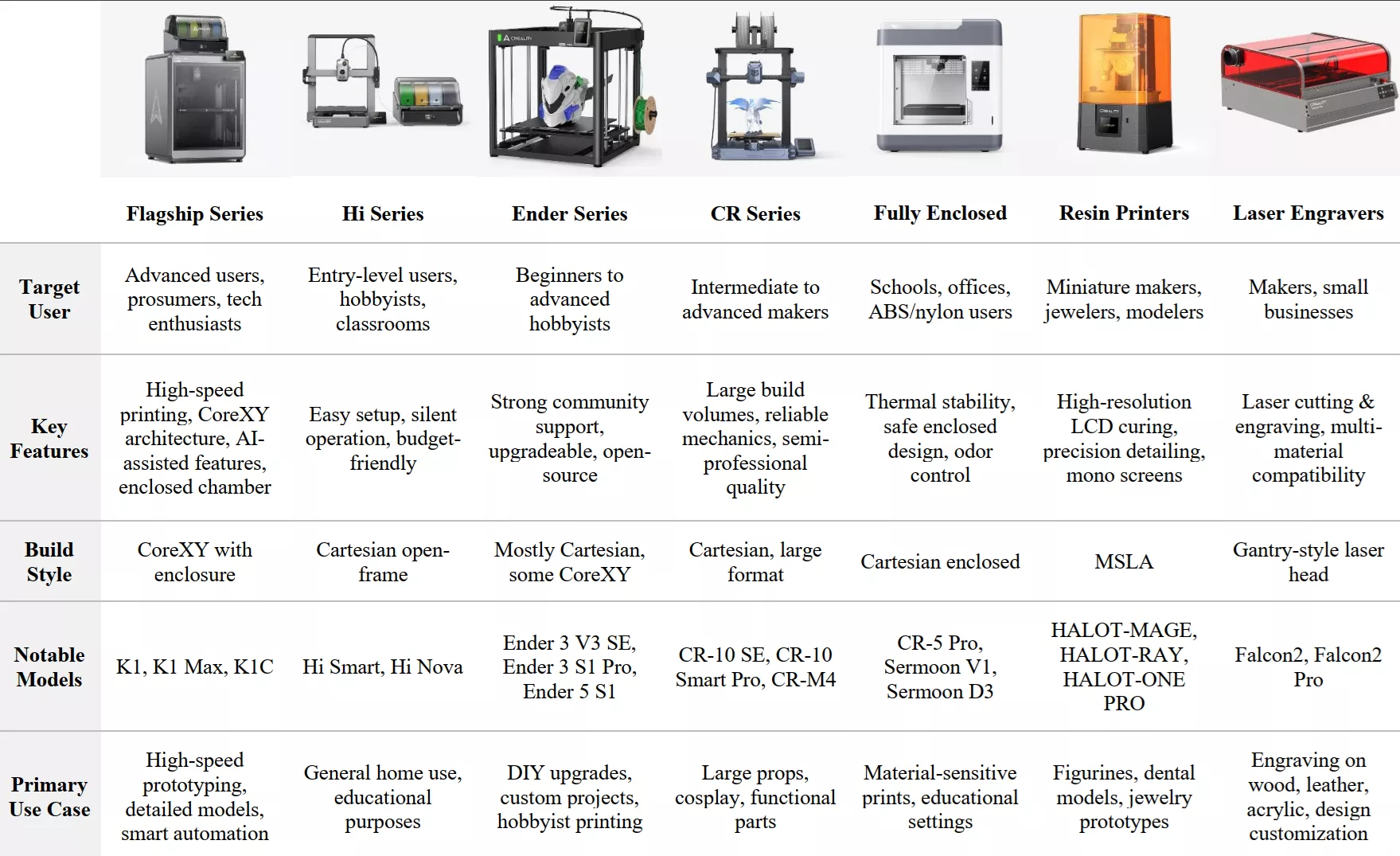

Founded in 2014, Creality has grown to become one of the most recognizable and influential brands in consumer 3D printing. Best known for democratizing access to affordable and capable printers like the Ender 3 and CR-10 series, Creality established itself by offering machines that deliver strong baseline performance at prices well below industry standards. Over the years, Creality expanded its lineup dramatically, catering to everyone from absolute beginners to advanced makers and professionals. With the introduction of high-speed CoreXY (a motion system that uses a different belt layout to allow faster and smoother movement) models like the K1 and K1 Max, Creality is evolving rapidly, although it still battles a reputation for inconsistent quality control on some earlier and budget models. The company's focus on openness, affordability, and a strong modding community (users who like to upgrade or modify their machines) continues to keep it at the forefront of the market.

Product Selection

4.2 /5

Creality is one of the most recognized names in 3D printing, known for its vast lineup across all price points — from beginner Ender kits to high-speed CoreXY machines like the K1 Max. It's a go-to brand for anyone who wants variety and modding freedom.

Ease of Use

3.5 /5

Creality's user experience has improved significantly over time. While early models like the original Ender 3 demanded manual bed leveling (manually adjusting the print surface to be flat relative to the nozzle) and considerable assembly, newer printers such as the Ender 3 S1, K1, and Ender 3 V3 series come semi-assembled with auto-bed leveling (automated bed adjustment using a sensor), touchscreen controls, and guided setup wizards. However, lower-end models may still require patience and mechanical skills during the initial setup and calibration phases. Overall, the learning curve has become much gentler in newer releases.

Cost & Affordability

4.9 /5

Affordability remains Creality’s core advantage. From ~$150 for an Ender 2 Pro to ~$600–$900 for a K1 Max, Creality offers excellent value across a wide range of budgets. Even larger printers like the CR-10 series maintain competitive pricing relative to their build volumes and capabilities. However, users should be aware that some low-end models may require early upgrades (e.g., hotend, springs, firmware updates) to achieve optimal performance, especially if they intend to print beyond basic PLA.

Print Quality & Speed

3.7 /5

Creality printers typically offer reliable print quality, especially in the Ender and CR-10 series. Layer lines (the visible horizontal lines that make up a printed object) are fine, dimensional accuracy is good with proper setup, and slicer profiles (pre-configured settings in slicing software that convert 3D models into printable instructions) are readily available for popular materials. While earlier models like the Ender 3 required significant tuning, newer models like the Ender 3 S1 Pro and K1 feature much improved out-of-the-box calibration. Speed-wise, traditional Cartesian models (printers where the bed or printhead moves along X, Y, and Z axes independently) like the Ender series operate at 50–100mm/s, but the newer CoreXY K1 and K1 Max models reach up to 600mm/s with advanced motion systems and active vibration compensation (a technology that reduces print artifacts caused by rapid movements). Still, maximum speeds often require fine-tuning to preserve surface quality, particularly on intricate prints.

Material Compatibility

4.2 /5

Material compatibility is one of Creality's biggest strengths. Their printers are designed to handle PLA (polylactic acid – easy-to-use plastic filament), PETG (polyethylene terephthalate glycol – durable and temperature-resistant), and TPU (thermoplastic polyurethane – flexible filament) with minimal effort, while upgraded models with all-metal hotends (the part of the printer that melts filament before extrusion) such as the Ender 3 S1 Pro and K1 Max extend support to ABS (acrylonitrile butadiene styrene – strong but temperature-sensitive), PC (polycarbonate), and nylon-based filaments. Open filament systems (printers that don’t require proprietary brand-specific filament) allow the use of third-party brands without restriction, making it easy and affordable to explore different materials. However, full performance with exotic filaments sometimes requires aftermarket modifications or enclosures (enclosed printer chambers to control temperature) on lower-cost models.

Build Volume & Variety

5.0 /5

Creality offers an extremely broad range of printer sizes. From the compact Ender 2 Pro for space-constrained users, to large-format machines like the CR-10 and CR-M4 with beds exceeding 400mm in one dimension, there's a Creality printer for nearly every project scale. This wide selection has been a major factor in their success, giving users options for miniatures, functional parts, cosplay props, and even small-batch manufacturing.

Reliability & Durability

3.6 /5

Mechanical durability is generally strong across Creality's product lines. Aluminum extrusion frames (metal structures that hold the printer together) and relatively sturdy motion systems (the belts and motors that move the printhead or bed) ensure long print life if properly maintained. Earlier generations (such as the Ender 3 and early CR-10s) suffered from inconsistent quality control, leading to occasional failures in components like hotends (melting unit), fans (cooling components), and mainboards (the printer's central control board). However, later models show notable improvement in build quality, better cabling, and more robust parts. Reliability is now on par with or superior to most competitors in the same price class.

Maintenance

4.4 /5

Maintenance is moderate but highly manageable. Parts are easily accessible and replacement components are inexpensive and widely available. Regular nozzle cleaning (removing residue from the print tip), belt tensioning (keeping movement belts tight for accuracy), and lubrication (applying grease to moving rods or rails) are simple for even novice users. Plus, the massive Creality user base ensures that troubleshooting guides, upgrade kits, and mods (user-made modifications) are always just a few clicks away. This strong aftermarket ecosystem makes Creality printers especially attractive to DIY enthusiasts.

Technology & Features

3.8 /5

Creality has been steadily adding more advanced features to their newer models. Auto-bed leveling, filament runout sensors (which pause printing if filament runs out), dual Z-axis setups (two motors to lift the printhead for better balance), silent stepper drivers (which reduce motor noise), flexible build plates (magnetic print surfaces that make object removal easier), and Wi-Fi connectivity are now standard on many printers. High-speed CoreXY models like the K1 and K1 Max introduce features like direct drive extruders (motors placed directly over the hotend for better filament control), fully enclosed chambers (for temperature-sensitive materials), AI camera monitoring (real-time print surveillance), and active flow control (for more accurate material extrusion). While innovation sometimes trails behind cutting-edge competitors like Bambu Lab, Creality has closed the gap significantly in 2023–2024 with much more competitive technology.

Conclusion

Creality has cemented its reputation as the go-to brand for accessible, versatile 3D printing. Its vast ecosystem, open-material approach, modular designs, and community support make it an ideal starting point for newcomers while still offering enough depth for advanced users. Although some lower-end models can demand tinkering (manual adjustment and upgrades) to unlock their full potential, Creality’s ongoing improvements and diverse lineup ensure there’s a machine suitable for almost any need—from basic hobby printing to advanced rapid prototyping.