Highlights

Exceptional high-speed printing with minimal quality loss (up to 500mm/s+ standard speeds)

Advanced multi-material and multi-color support via AMS system

High-end features like LIDAR-assisted bed leveling and active vibration compensation

Fully enclosed, premium-grade build quality in flagship models

Seamless software integration with Bambu Studio and mobile app

Proprietary but flexible ecosystem with third-party filament compatibility

Effortless setup and calibration for beginner to advanced users

Strong future-proofing with frequent firmware updates and expanding ecosystem

Bambu Lab is a relatively young player in the consumer 3D printing market, having entered the scene with a bold focus on speed, automation, and user-friendly design. Founded by a team of former DJI engineers (the company known for drones), Bambu gained attention with its flagship X1 series, which introduced features like LIDAR calibration (laser-based scanning for precise bed leveling), multi-material printing, and deeply integrated hardware-software ecosystems.

Unlike brands rooted in open-source or DIY backgrounds, Bambu Lab aims to deliver a more “appliance-like” experience—fast, quiet, and seamless. Their printers are built for users who want professional-level results without constant tinkering, making them ideal for busy hobbyists, schools, designers, and light industrial use.

Product Selection

4.4 /5

Bambu Lab brings a sleek, high-tech approach to 3D printing — fast, smart, and beginner-friendly. With innovations like LIDAR calibration and the AMS system, it’s perfect for prosumers and professionals who want speed without tinkering.

|

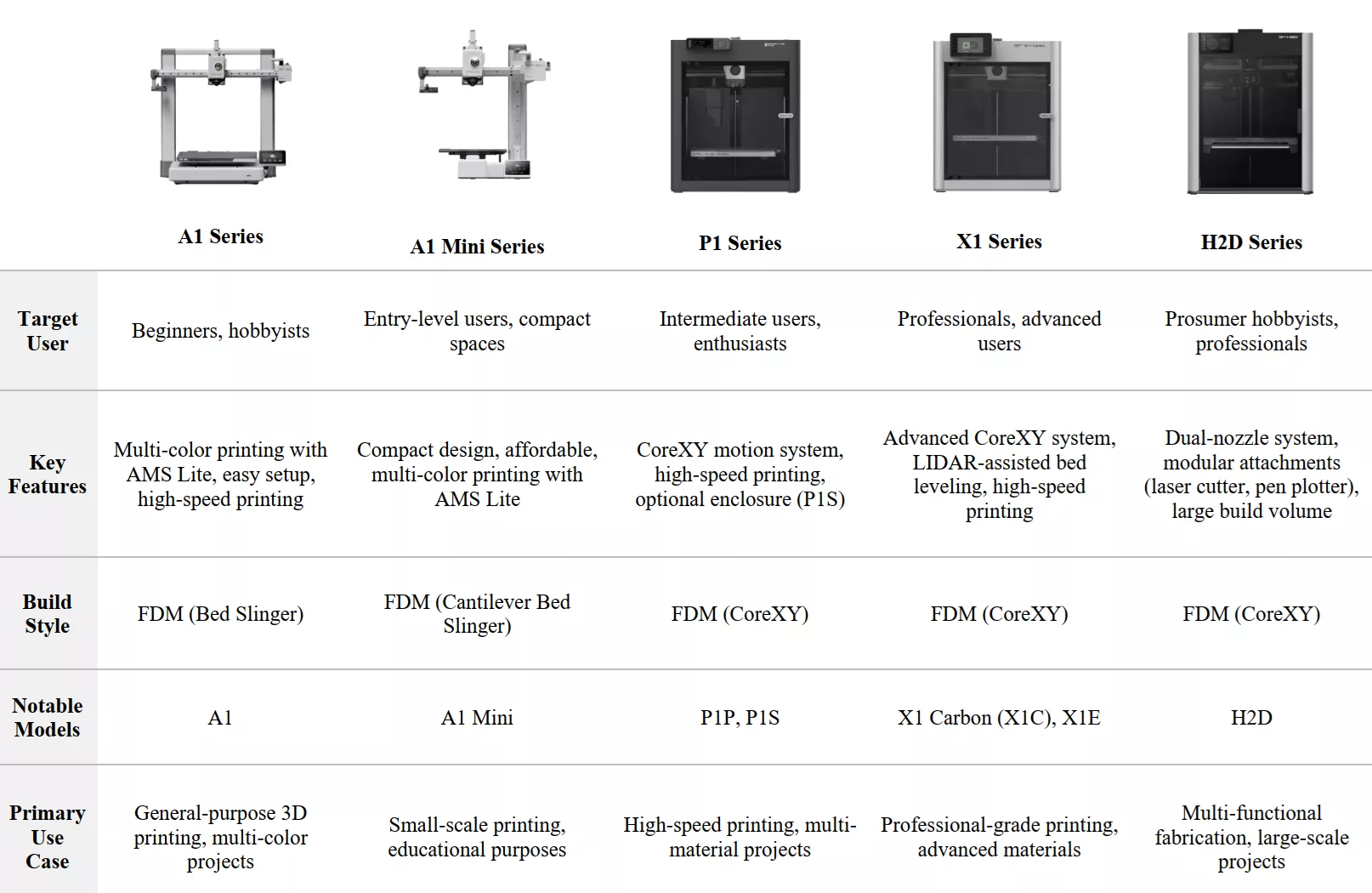

A1 Series |

A1 Mini Series |

P1 Series |

X1 Series |

H2D Series |

|

| Target User | Beginners, hobbyists | Entry-level users, compact spaces | Intermediate users, enthusiasts | Professionals, advanced users | Prosumer hobbyists, professionals |

| Key Features | Multi-color printing with AMS Lite, easy setup, high-speed printing | Compact design, affordable, multi-color printing with AMS Lite | CoreXY motion system, high-speed printing, optional enclosure (P1S) | Advanced CoreXY system, LIDAR-assisted bed leveling, high-speed printing | Dual-nozzle system, modular attachments (laser cutter, pen plotter), large build volume |

| Build Style | FDM (Bed Slinger) | FDM (Cantilever Bed Slinger) | FDM (CoreXY) | FDM (CoreXY) | FDM (CoreXY) |

| Notable Models | A1 | A1 Mini | P1P, P1S | X1 Carbon (X1C), X1E | H2D |

| Primary Use Case | General-purpose 3D printing, multi-color projects | Small-scale printing, educational purposes | High-speed printing, multi-material projects | Professional-grade printing, advanced materials | Multi-functional fabrication, large-scale projects |

Ease of Use

4.7 /5

Ease of use is one of the core design pillars of Bambu Lab printers. Most models are nearly plug-and-play, requiring very little setup beyond unboxing and running initial calibrations. Key convenience features include automatic bed leveling (where sensors ensure the print bed is perfectly flat), filament runout detection (which pauses the print if the filament runs out), flow calibration (which fine-tunes how much material is extruded), and intuitive touchscreen interfaces. The Bambu Handy mobile app and Bambu Studio desktop slicer both offer clean, beginner-friendly interfaces while still allowing advanced customization for experienced users. The only area with a slight learning curve is the AMS unit; managing multi-material or multi-color jobs may require a few rounds of calibration and familiarization, but the long-term workflow remains highly efficient.

Cost & Affordability

4.3 /5

Bambu Lab offers competitive pricing given the premium features included in its printers. The A1 Mini Combo, which includes AMS support for multi-color printing, is priced under $300, making it one of the most feature-rich entry-level printers on the market. The P1P and X1-Carbon range between $600 and $1,200, depending on selected options and bundles, placing them between hobbyist and professional pricing tiers. While the printers are not as inexpensive as budget models from Creality or Anycubic, the combination of performance, automation, and ecosystem maturity delivers strong value. However, the semi-proprietary nature of the AMS and limited third-party filament integration may add indirect costs for users who prefer open platforms.

Print Quality & Speed

4.8 /5

Print quality and speed are standout strengths for Bambu Lab. Models like the X1-Carbon and P1P consistently produce sharp, dimensionally accurate prints, meaning the final objects match design specifications with minimal warping or distortion. Surface finishes are typically smooth, and layer lines are clean even on default settings. These printers operate at default speeds exceeding 250 millimeters per second, supported by a CoreXY motion system (a design where the print head moves diagonally for smoother and faster operation) and active vibration compensation that stabilizes movement during printing. Even at these high speeds, print fidelity is preserved in most use cases. For extremely detailed miniatures or precise mechanical components, slowing down can still yield sharper results, but for the majority of projects, the balance between speed and quality is excellent.

Material Compatibility

4.1 /5

Bambu Lab printers offer robust support for standard filament types such as PLA (a biodegradable, easy-to-use plastic), PETG (a stronger, more heat-resistant material), and TPU (a flexible rubber-like material). Higher-end models like the X1 series extend that range to more demanding filaments including ABS (impact-resistant and heat-sensitive) and Nylon (durable and slightly flexible), thanks to features like fully enclosed chambers that maintain a stable temperature and high-temperature hotends capable of reaching over 300°C. However, the brand’s proprietary Automatic Material System (AMS)—an advanced multi-spool feeder designed for multi-color and multi-material jobs—works best with Bambu’s own filament spools. While third-party filaments are usable, users may need to manually adjust slicer settings or tweak profiles, especially in multi-material projects. This semi-closed approach may feel slightly less convenient for users who prioritize open compatibility.

Build Volume & Variety

3.5 /5

Bambu Lab's product line covers the most common build volume categories but does not currently include large-format machines. Models like the P1P and X1-Carbon offer a mid-size 256 x 256 x 256 mm build volume, which suits most general-purpose printing tasks from household items to mechanical prototypes. The A1 Mini caters to users with smaller workspaces or interests in miniatures, offering a 180 x 180 x 180 mm print area. While the selection lacks breadth compared to brands offering dozens of form factors, the available models strike a smart balance between compact footprint and build capacity, making them highly practical for desktop users.

Reliability & Durability

4.4 /5

Build quality in Bambu Lab printers is impressive, with rigid aluminum frames, quality stepper motors, and carefully engineered mechanical components designed to withstand long print sessions without failure. The CoreXY structure also reduces mechanical wear over time by balancing forces more evenly across motion axes. While the hardware itself is durable, some users have reported occasional interruptions due to firmware bugs or Wi-Fi connection issues. Fortunately, Bambu Lab frequently pushes software updates that quickly address known issues. Mechanically, the printers remain stable and consistent, making them well-suited for continuous use in demanding environments.

Maintenance

4.2 /5

Maintenance is generally manageable and supported by modular design elements. Components such as the hotend, fans, and sensors are easy to access and replace, and Bambu Studio includes diagnostic tools to identify common issues before they lead to failed prints. The online user community also contributes actively with troubleshooting guides, printable upgrades, and firmware tips. However, accessing certain internal components—especially in AMS-equipped or fully enclosed models—can be slightly more involved than with open-frame printers. Also, since the printers operate at higher speeds and temperatures, consumables like nozzles may require more frequent replacement. Overall, though, the maintenance experience is predictable and user-friendly.

Technology & Features

4.9 /5

Bambu Lab sets itself apart with its suite of high-end features. The X1 series, for instance, includes LIDAR-assisted first-layer inspection, where a laser scans the first layer of a print to ensure perfect adhesion. Active vibration compensation improves motion smoothness and print quality, while ultra-quiet operation makes the machines suitable for use in shared workspaces or homes. The AMS unit enables fully automated multi-material printing with up to four filament spools, and all printers include resume-on-power-loss capabilities and intelligent thermal regulation. Bambu Studio integrates cloud printing, local LAN access, and mobile app control, providing one of the most polished and responsive software ecosystems in the 3D printing space. While the ecosystem is semi-closed—optimized for Bambu’s own hardware and filament—it delivers an experience that is efficient, seamless, and far more refined than typical hobby-grade platforms.

Conclusion

Bambu Lab has rapidly set a new standard in 3D printing by delivering fast, smart, and reliable machines with a seamless user experience. While their ecosystem leans toward proprietary tools, the blend of ease of use, industrial-grade features, and competitive pricing makes them ideal for serious hobbyists, educators, designers, and small businesses.

If you're someone who values efficiency, quality, and automation over deep hardware customization, Bambu Lab printers offer some of the most compelling options on the market today.

.webp)

.webp)